Do you know how to use rotary kiln make activated carbon by steam activation method

How is activated carbon made? /What's the raw materials?

Activated carbon is commercially manufactured from coal, wood, fruit stones (mainly coconut but also walnut, peach) and derivatives of other processes (gas raffinates). Of these coal, wood and coconut are the most widely available.The product is manufactured by a thermal process, but in the case of raw materials such as wood, a promoter (such as an acid) is also used to develop the required porosity.Downstream processes crush, screen, wash and/or grind the multitude of products to the client's requirements.

Xingyuan Activated Carbon Steam Activation –Rotary Kiln

Steam activation is the most widely used process because it is generally used to activate both coconut shell and coal based carbons. Steam activated carbons are produced in a two-stage process. Firstly the raw material, in the form of lumps, pre sized material, briquettes or extrudates, is carbonized by heating in an inert atmosphere such as flue gas, so that dehydration and devolatilization of the carbon occur. For this stage temperatures usually do not exceed 700 C. Carbonization reduces the volatile content of the source material to under 20%. A coke is produced which has pores that are either small or too restricted to be used as an adsorbent.The second stage is the activation stage which enlarges the pore structure, increases the internal surface area and makes it more accessible.

The carbonized product is activated with steam at a temperature between 900C and 1100C. The chemical reaction between the carbon and steam takes place at the internal surface of the carbon, removing carbon from the pore walls and thereby enlarging the pores. The steam activation process allows the pore size to be readily altered and carbons can be produced to suit specific end-sues. For an example, the pore structure has to be opened up more for the adsorption of small molecules from a solution, as in water purification, than for the adsorption of large colour molecules in sugar decolorization.Steam Activation produce activated carbon in the from of 1mm to 3mm pieces, which are crushed and screened to remove fines and dust to meet the specifications for granular activated carbons. To produce powdered activated carbons, the carbon pieces are further ground using a gentle pulverizing action.

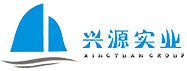

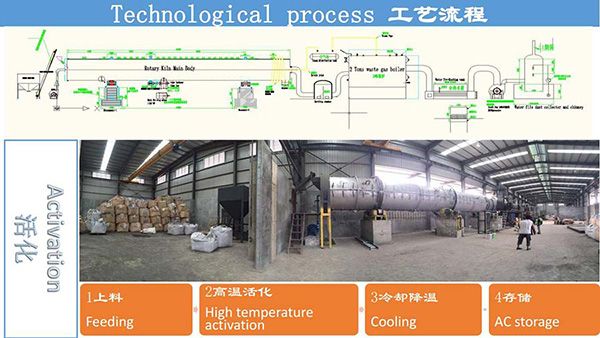

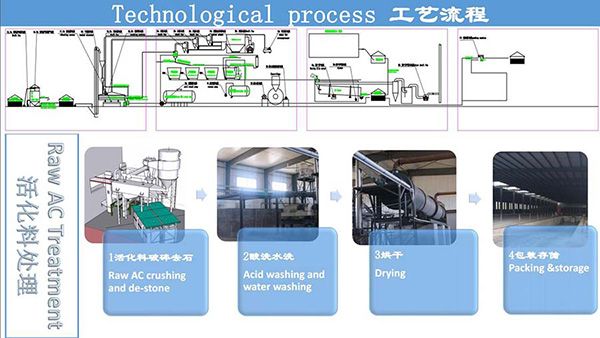

Explanation for Rotary Kiln Production Line Procedure:

1-Raw materials need to carbonize first before feeding into the activated carbon rotary kiln. Can use Xingyuan carbonizing furnace for shell and bamboo biomass carbonizing.

2-After get the charcoal, use Xingyuan activated carbon making machine for steam activation. with high temperature 8000-1100degree, and about 12hours activation, can get the good quality of activated carbon products.Charcoal by feeding-activation-cooling than can be stocked for crushing and milling process.

3-After activation by xingyuan rotary kiln, according to the customers' request, the raw activated carbon need to be crushed –packing –selling. but for some special request, need extra acid washing treatment.

4—Testing is very important during the activated carbon running

What equipment should equipped in a activated carbon factory?

A steam activation factory should be equipped its factory according to the procedure:

1---Carbonizing furnace, change the biomass into charcoal first.

2---Charcoal treatment, meshing and crushing .

3---Steam activated carbon making machine.

4---Raw AC. Treatment system, crushing and milling, also including acid washing or other procedure.

5---A lab for testing.

This set of new technology 5th+ activated carbon rotary kiln composition:

1- Feeding systems

2- Activated carbon rotary kiln main body

3- Output system

4- Temperature testing system

5- Steam Creating system

6- Waste gas treatment and discharge