Xingyuan Activated Carbon Regeneration Rotary Kiln

---Stable produce high reactivation

---Automatic operation.

---Easy maintaince

---Low fuel consumption

---Xingyuan Biomass Equipment Brand---

What is the activated carbon regeneration? Or what's meaning activated carbon reactivation?

Waste activated carbon regeneration, often referred to as reactivation, is a method of thermally processing the activated carbon to destroy the adsorbed components contained on its surface. In regeneration, the adsorbed components are almost completely removed, yielding a regenerated carbon that can again function as an adsorbent.

In the adsorption process, carbon activity and adsorption capacity are decreased through organic fouling contamination with fuel and lubricants from processing equipment, flotation reagents, grinding aids, viscosity modifiers, humic acids and plastics.

Organic fouling slows the gold and silver adsorption rate and decreases the metal loading capacity of the carbon. Precious metals losses occur as available gold and silver cyanide ions are not captured by the carbon. Remaining precious metal inventory builds within the circuit leading to higher soluble losses to tailings.

That's where our carbon regeneration kilns can restore activity of fouled or 'contaminated' carbon for a far more sustainable approach versus purchasing new activated carbon. Eliminate the cost of disposing of fouled carbon which still has useful life, all while incurring fewer greenhouse gas emissions.

How to reactivation the spend activated carbon?

Spent (waste) granular or pelletized or Powder activated carbon can be recycled by thermal reactivation, in which the spent carbon is processed through a high temperature reactivation furnace at or above 850°C. The adsorbed organics on the carbon are thermally decomposed. The resulting gases are fed through an afterburner and a treatment system to allow emission to atmosphere in accordance with most stringent environmental regulations. Recycling by thermal reactivation is an environmentally responsible disposal method that helps to reduce CO2 emissions over the activated carbon and contributes to a sustainable use of the world’s resources.

It’s important to note that regeneration and reactivation actually refer to two technically different processes. However, these terms are frequently used interchangeably across many industries, and as such, are used so in this article.

According to the type of equipment, Xingyuan have two type of reactivation kiln for the spend activated carbon.

A: Rotary kiln activated carbon reactivation production line

This Rotary kiln regeneration line is suitable for the GAC(granular activated carbon) and Pelletized activated carbon, NOT suitable for the powder type activated carbon.

B: Tunnel Kiln activated carbon reactivation production line

This Tunnel kiln can used for the power type of activated carbon.

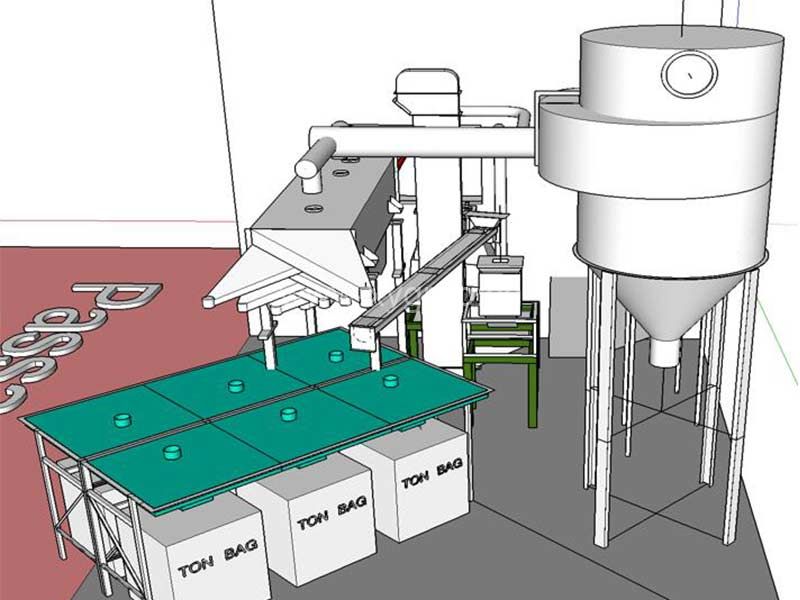

Xingyuan GAC (granular activated carbon) reactivation production line

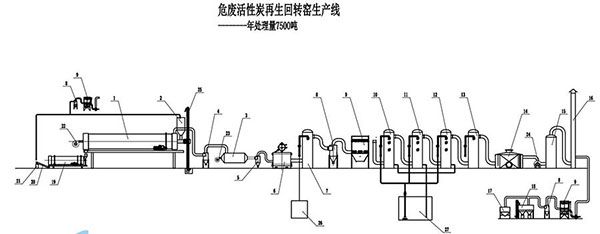

Xingyuan Activated carbon regeneration production line flow chat

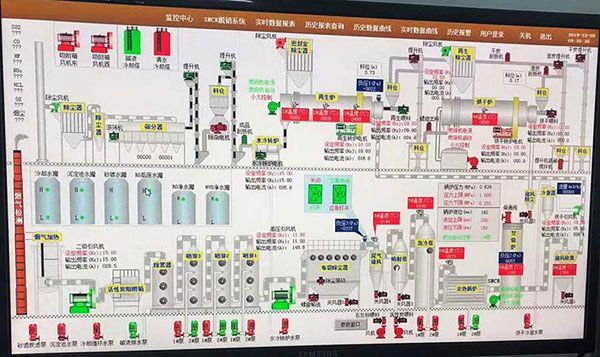

AC Reactivation Plant Computer Monitoring System

Xingyuan Activated Carbon Regeneration Project

Spend activated carbon can be separated into Hazardous Waste and General Solid Waste

For example:

Spend activated carbon from chemical or medicine industry will be the hazardous waste, and Spend activated carbon from sugar or oil factory will be the General Solid Waste.

This two different type of waste can all use our reactivation production line, but the waste gas treatment design will be little different, in another words, in Hazardous waste treatment, need equipment to remove the Dioxin. So the Dioxin Remove process will be the main different between Hazardous Waste and General Solid Waste activated carbon regeneration flow design.

Activated Carbon Reactivation Rotary Kiln Production Line

Xingyuan Activated Carbon Regeneration Rotary Kiln Specification

| Model No. | Size MM | Spend AC Treatment Capacity (MT/DAY) | Remark |

| XYRACM-R01 | 15000(L)*1500 (Dia.) | 10 | ACCORDING TO DIFFERENT SPEND MOISTURE CONTENT |

| XYARCM-R02 | 16000(L)*1800 (Dia.) | 12 | |

| XYARCM -R03 | 17000(L)*2000 (Dia.) | 12-15 | |

| XYARCM -R04 | 18000(L)*2200 (Dia.) | 15-18 | |

| XYARCM -R05 | 20000(L)*2400 (Dia.) | 18-22 | |

| XYARCM -R06 | 24000(L)*2800 (Dia.) | 22-30 |

Remark: Because the spend activated carbon moisture if different from 15-35%, so the daily treatment capacity will be different .

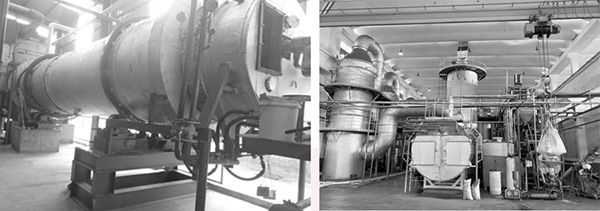

Now Xingyuan two Type of Activated Carbon regeneration kilns

A: Rotary Kiln—Granular activated carbon reactivation kiln

B: Tunnel Kiln—Powder activated carbon regeneration kiln

ITEMS | AC Reactivation Rotary Kiln |

PIC |  |

Principle | Heating high temperature reactivation |

Main material | 1. Manganess steel body |

Spend AC | 1. GAC (granular size spend AC) |

Size: | (18-25)Length * (1.5-2.5 dia)m for kiln body , whole set take place 35m *10m |

Temperature | 750-950 degree |

Fuel | Natural Gas, coal, bio-pellets |

Treatment | 10-50MT per day |

Project time | 40days installation,10days training, 30days running, totally 3month |

Start fire | first time 3days, after 1day |

Electricity | 260KW.H per hour |

Fuel consumption | natural gas 6000CBM/DAY |

Advantage | 1. Stable produce high reactivation |

Dis-Advantage | 1. electricity cost high |

Contact us for more information:

We can supply the right and best solution for your factory according to the different country and different situation products, Please contact with us and let us know your simple information and request for our products, we will feedback as soon as possible.